Microdot Fusible Interlining: The Modern Backbone of Garment Structure

In garment manufacturing, precision and finish define quality. Among the many innovations improving garment structure, Microdot Fusible Interlining stands out for its accuracy, softness, and durability. This advanced interlining fabric is designed to bond perfectly with outer fabrics — giving garments a refined shape without stiffness or surface marks.

Whether used in shirts, jackets, or uniforms, Microdot Fusible Interlining delivers strength, flexibility, and consistent adhesion — making it an essential component for the fashion and apparel industry.

What is Microdot Fusible Interlining?

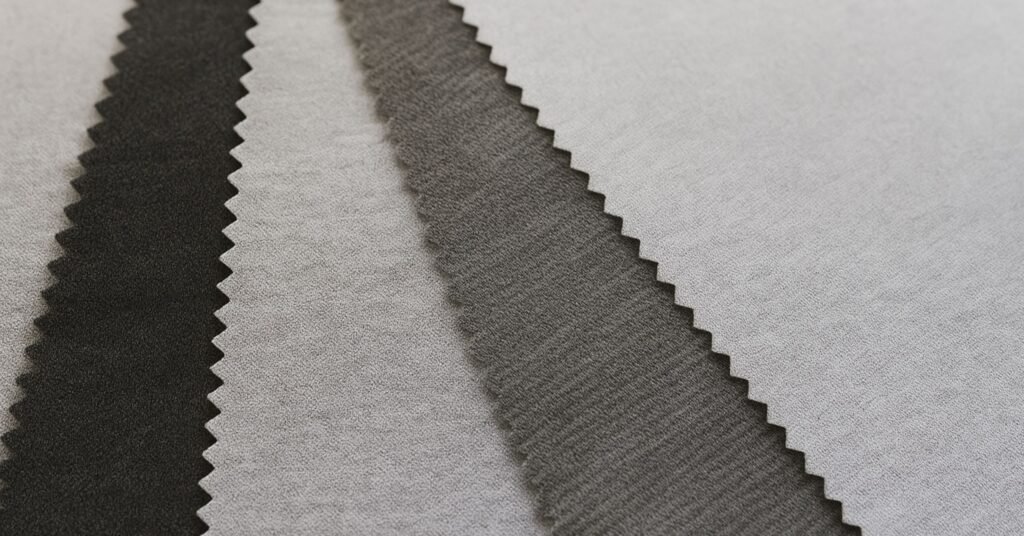

Microdot Fusible Interlining is a specialised interlining fabric coated with minute adhesive dots using precision coating technology. These microdots, when heated and pressed, create an even bond between the interlining and the fabric.

Unlike traditional fusibles that can create uneven texture or bubbling, microdot interlining offers a smooth surface and soft handle, maintaining the garment’s natural drape while ensuring long-lasting structure.

Distinct Features of Microdot Fusible Interlining

- Even Adhesive Distribution: Each dot is applied uniformly to prevent strike-through.

- High Bonding Strength: Ensures firm attachment to a wide range of fabrics.

- Soft and Flexible: Keeps the garment’s original feel intact.

- Wash & Dry-Clean Safe: Adhesion remains strong after repeated care cycles.

- Customizable Options: Available in various GSMs, coatings, and widths.

Common Types of Microdot Fusible Interlining

- Woven Microdot Interlining: Ideal for formal and structured garments, this type offers both flexibility and firmness.

- Non-Woven Microdot Interlining: Lightweight and cost-effective, suitable for mass garment production and everyday wear.

- Knitted Microdot Interlining: Best for stretch fabrics — provides elasticity and shape retention without adding bulk.

Applications Across the Garment Industry

- Dress shirts and formal wear

- Suits, blazers, and jackets

- Uniforms and corporate clothing

- Traditional and ethnic garments

- Garments requiring a smooth structure and comfort

Advantages of Using Microdot Fusible Interlining

- No visible adhesive marks on the surface fabric

- Perfect bonding even under moderate heat

- Enhances garment strength without stiffness

- Works well on lightweight and premium fabrics

- Compatible with automatic fusing machines

Why Choose a Reliable Manufacturer

Working with an experienced Microdot Fusible Interlining Manufacturer in India ensures quality control, coating consistency, and reliable customisation. A reputed manufacturer like M.Lachhmandas & Co. offers both woven and non-woven variants engineered for high performance, ensuring every garment maintains its form and feel.

They also provide support for bulk orders, export supply, and testing based on international garment standards.

How to Select the Right Microdot Interlining

- Match GSM and coating with your base fabric.

- Test bonding temperature before production.

- Choose woven or non-woven depending on the garment type.

- Always use certified interlinings for export-quality garments.

Conclusion

Microdot Fusible Interlining is redefining how garments are shaped, fused, and finished. Its micro-level coating precision ensures smooth adhesion, superior strength, and comfort — qualities that every premium garment demands.

If you’re sourcing Microdot Fusible Interlining in India, choose a manufacturer that prioritises innovation, quality, and performance — like Talreja Textiles, a trusted name for interlining solutions across India and abroad.